Designing a new hydroelectric power station can be a laborious task - the pressures, temperatures and fluid flows can be simulated but the actual results outside FEA showbiz graphics will still be columns of numbers or a one-dimensional representation which need analysis.

A new technique could make the process a lot more elegant. Scientists from the Fraunhofer Institute for Factory Operation and Automation IFF in Magdeburg have developed a method that visualizes the processes inside energy conversion plants, e.g. such as photovoltaic, wind, biogas and hydroelectric power stations. To do so, they have coupled 3-D plant engineering and simulation results with a virtual reality (VR) program developed at the IFF.

"A special software tool has enabled us to visualize all the motion sequences for the first time ever – at just the push of a button," explains Dr. Matthias Gohla, Manager of the Process and Plant Engineering Business Unit.

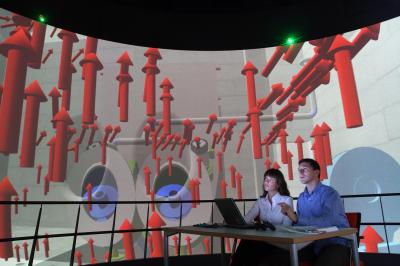

Engineers developing a combustion plant use a new VR model to study the direction in which gases will flow through it. Credit: Dirk Mahler / Fraunhofer IFF

Arrows that move through the VR model show engineers the direction in which and speed at which fluids and gases flow through a plant. Colored markings indicate potential weak points such as areas where critical temperatures, deposits or erosions could occur. Is there a potential for collisions when the plant components are moving? The virtual insights facilitate engineering and should therefore ensure that plants become more efficient and have lower emissions.

"Our VR model also helps plant operators in day-to-day operation," says project manager Dr. Martin Endig. For instance, extensive documentation may be implemented in the system.

Instead of hunting through thick instruction manuals for desired information, a technician merely needs to click on the appropriate representation to obtain data on a certain plant component.

Moreover, personnel can be trained to handle a plant before it is operational. Even critical situations can be simulated without endangering employees.

Currently, the developers are working on another tool that notifies operators when a component is due for maintenance.